- Automation engineers design, implement, and maintain integrated hardware–software systems that enhance efficiency, safety, and reliability across industries.

- Key skills include programming (Python, C/C++, PLC logic), control systems, data/AI literacy, and cross-disciplinary communication.

- Global demand for automation engineers is rising rapidly due to Industry 4.0, AI integration, and workforce shortages across sectors.

As someone who’s spent years designing, deploying, and optimizing automated systems across industries, I can tell you this: the role of the automation engineer isn’t just growing, it’s evolving at a pace that demands attention. Whether you’re overseeing a manufacturing plant, running DevOps for a SaaS company, or orchestrating robotic logistics in e-commerce, automation is not just a toolset; it’s a strategic edge.

Let’s break down the profession in the most practical, real-world terms possible, from the core responsibilities and required skills to career paths, tools of the trade, and where this profession is heading.

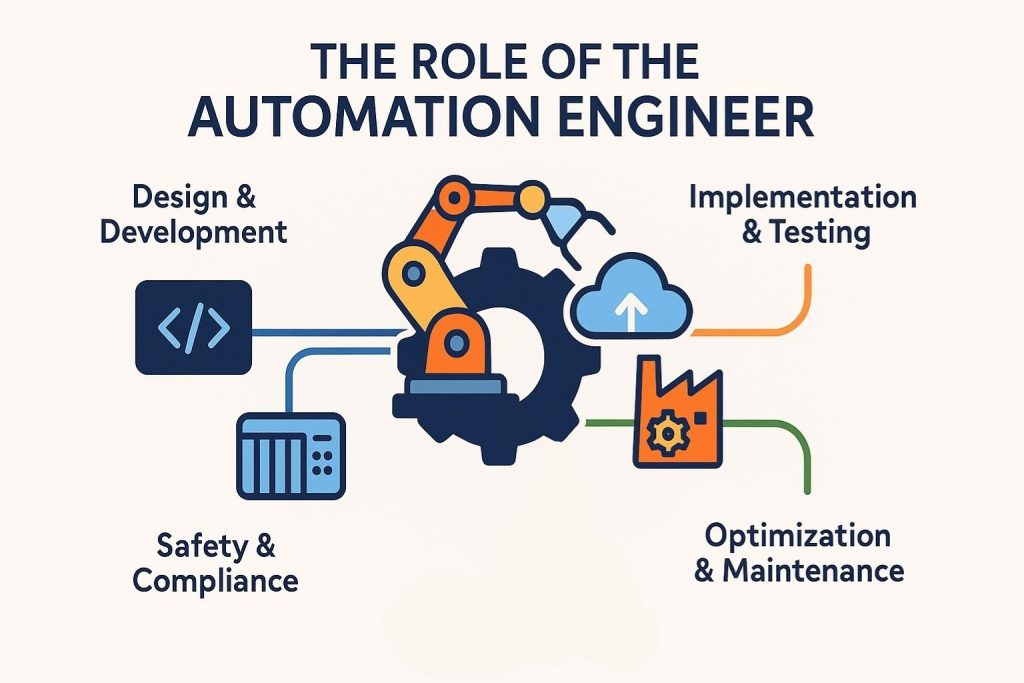

Job Roles and Responsibilities

Automation engineering sits at the intersection of software, hardware, and process design. It’s a hands-on discipline, and it looks different depending on the domain you work in. But the foundational responsibilities remain consistent. Here’s how I approach them in the field.

Designing and Developing Automated Systems

The work begins with understanding the problem. Whether it’s a repetitive manual task in a production line or a flaky deployment process in a CI/CD pipeline, the first step is always defining what should be automated and why.

Once we’ve identified the opportunity, we move into designing the solution. That could involve:

- Selecting sensors, actuators, or virtual tools

- Creating control logic (ladder logic, structured text, or high-level languages)

- Building flow diagrams and system architecture

- Writing the code that connects everything

In industrial contexts, that might mean PLCs and SCADA systems. In software, we could be dealing with Jenkins pipelines, Python scripts, or cloud automation APIs.

Implementing and Testing

No design survives first contact with reality. Once deployed, every system has edge cases you didn’t model or behaviors you need to calibrate.

This is where I spend a good portion of my time writing and executing test cases, validating every possible input and output, simulating failures, and ensuring the system is robust.

Testing here includes:

- Hardware diagnostics and safety testing

- Automated QA scripts and API validation

- Integration testing between physical systems and their digital controllers

Maintaining and Optimizing Systems

Automation isn’t a “set and forget” game. Systems degrade, requirements evolve, and new technologies emerge.

Maintenance includes monitoring logs, adjusting parameters, applying firmware or software updates, and occasionally replacing hardware. But more than that, we’re always looking for ways to improve:

- Can we reduce cycle time?

- Can we increase fault tolerance?

- Can we make the interface more intuitive?

Continuous improvement is baked into the job.

Ensuring Safety and Compliance

In regulated environments, pharma, food, oil and gas, and medical devices compliance is non-negotiable.

We’re responsible for:

- Functional safety audits (SIL ratings, risk assessments)

- Validating that automated systems meet standards (e.g., FDA 21 CFR Part 11, ISO 13849)

- Creating proper documentation trails

You can’t afford to shortcut this step. I’ve seen entire projects delayed by non-compliance that could have been avoided early on.

Collaboration and Cross-functional Integration

This isn’t a solo sport. I collaborate daily with mechanical engineers, electricians, software devs, QA analysts, safety officers, and project managers.

We speak different technical languages, so being able to translate between electrical schematics, flowcharts, and source code is a key part of the job.

In large organizations, I’m often pulled into early-stage discussions to help teams understand what’s feasible to automate and what’s not. That’s where the real value of experience shows.

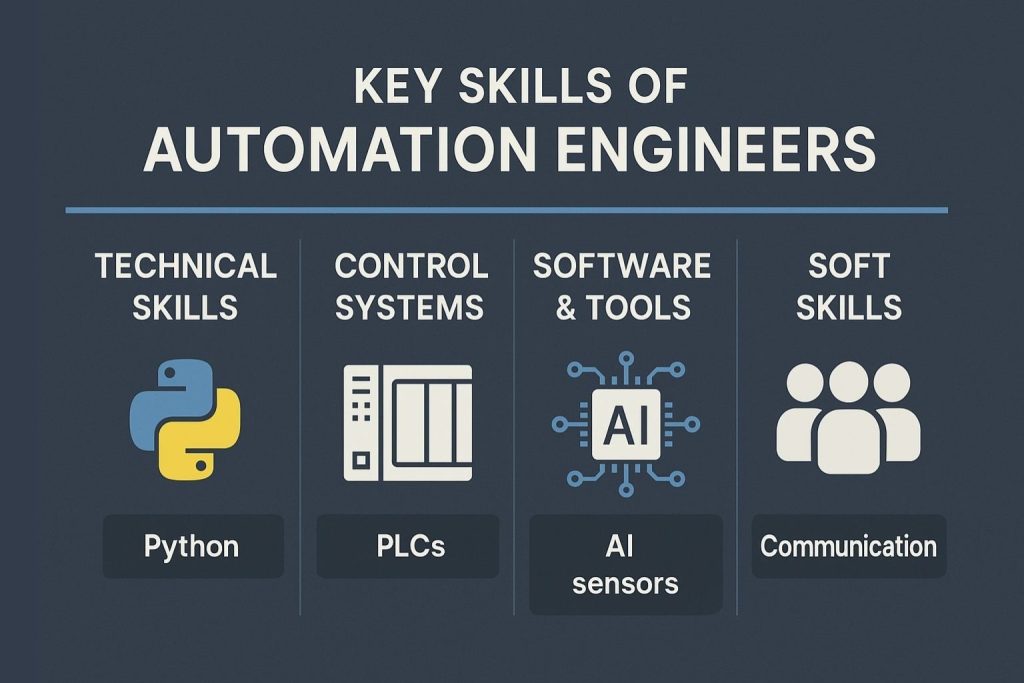

Skills and Qualifications

You won’t succeed in this field with just a few programming courses or a knack for tinkering. Automation engineering is multidisciplinary by design. You need breadth and depth. Let me break it down.

Technical Skills

Programming and Software Development

If you can’t write and debug code, you’re at a disadvantage. The most useful languages vary by sector:

- Python for scripting, data analysis, and test automation

- Java and C# in enterprise and software QA environments

- C/C++ and structured text for embedded systems and PLCs

- SQL for database automation and integration

You’ll also need to understand basic software design patterns and version control (Git, SVN) to collaborate effectively on larger projects.

Electrical and Mechanical Knowledge

You won’t be designing PCBs or machining parts, but you need to understand:

- Sensor technologies (analog/digital, photoelectric, ultrasonic)

- Motors and actuators (stepper, servo, pneumatic)

- Power systems (12VDC, 24VDC, 480VAC)

- Control systems theory: PID loops, hysteresis, open-loop vs closed-loop systems

This lets you interface intelligently with hardware teams and troubleshoot physical issues when they arise.

Control and Automation Systems

The bread and butter of manufacturing. Expect to work with:

- PLCs (Allen-Bradley, Siemens, Omron)

- SCADA systems for real-time monitoring and data visualization

- HMI software for operator control panels

- Robotics platforms (FANUC, ABB, Universal Robots)

In IT or DevOps roles, you’ll trade that for tools like Ansible, Jenkins, Docker, and Kubernetes. But the control logic mindset still applies.

Testing Frameworks and Automation Platforms

In software-centric roles, I’ve leaned on tools like:

- Selenium, Postman, and Cypress for test automation

- Jenkins, GitLab CI, CircleCI for continuous integration and deployment

- Robot Framework, Appium, and LoadRunner for specific verticals (mobile, performance)

If you’re in a QA automation track, your value is directly tied to how robust and maintainable your test suites are.

Data and AI Literacy

Increasingly, we’re integrating AI and machine learning into automation. Think:

- Predictive maintenance using vibration or temperature data

- Machine vision with OpenCV or TensorFlow

- AI-powered process control that adapts in real time

You don’t need to be a data scientist, but you should understand the concepts and be able to collaborate effectively with ML engineers.

Soft Skills

Problem-Solving

Every automation project starts with a problem and ends with a thousand little workarounds. Creative troubleshooting is the job. This includes both debugging existing systems and architecting new ones under constraints (space, budget, legacy tech).

Communication

You need to explain technical tradeoffs to non-technical people. I’ve presented to executives, trained technicians, and debated PLC logic with electricians, sometimes all in one day. If you can’t tailor your message to your audience, your automation will never get deployed.

Leadership and Project Ownership

As you grow, you’ll start owning full systems or projects. That means setting timelines, coordinating teams, and taking responsibility when things break (and they will).

Curiosity and Adaptability

Automation isn’t static. I’ve had to pick up new tools on the fly, reverse-engineer undocumented systems, and adapt to changing specs a week before go-live. If you’re not comfortable with constant learning, this job will eat you alive.

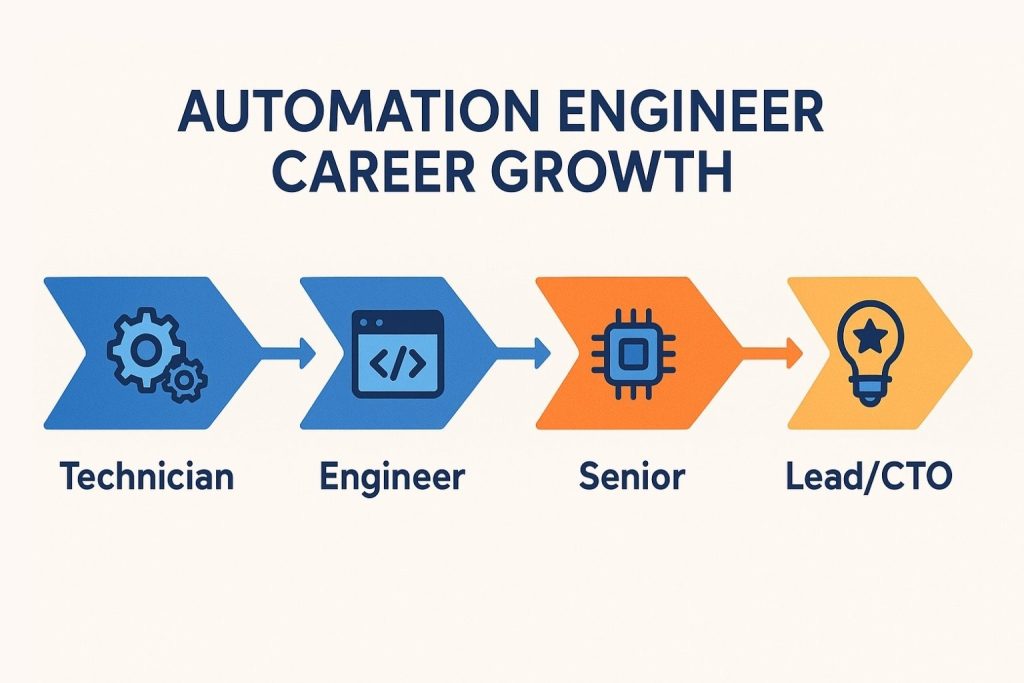

Career Path and Education

This profession doesn’t have a single, linear path. I’ve worked with automation engineers who came up through electrical apprenticeships, software QA, mechanical engineering, and even data science. But there are common entry points and patterns I’ve seen work well.

Typical Educational Pathways

For most, it starts with a Bachelor’s degree in one of the following:

- Automation Engineering

- Electrical or Electronic Engineering

- Mechanical Engineering

- Mechatronics

- Computer Science or Software Engineering

These programs give you the math, control theory, and programming fundamentals that you’ll build on for years.

That said, I’ve seen technicians without formal degrees master PLCs, SCADA, and ladder logic through industry training and become indispensable in plant environments. So while a degree helps, it’s not the only way in.

What matters more is your ability to demonstrate skill, solve problems, and communicate clearly with multidisciplinary teams.

Internships and Early Experience

If you’re just starting out, internships and co-ops are gold. They give you exposure to real systems, help you build a portfolio, and teach you the operational realities you never learn in class. Even shadowing a senior technician on a machine line can teach you more than a semester of theory.

Your first role might be:

- Automation Technician

- Junior Automation Engineer

- QA/Test Automation Analyst

- Controls Engineer (Entry-Level)

This is your chance to learn from those who’ve been in the trenches. Watch how they troubleshoot, how they handle failure, how they explain tradeoffs to project managers. That’s how you grow.

Certifications and Professional Development

Certifications can set you apart, especially when they align with your role. A few worth considering:

- Certified Automation Professional (CAP) – Offered by ISA; ideal for systems-level automation work

- Certified Control Systems Technician (CCST) – For hands-on industrial techs

- Certified Tester Advanced Level Test Automation Engineering (CTAL-TAE) v2.0 – For those in software QA automation

- PMP or Agile/Scrum Certifications – If you’re leading projects

I’ve seen clients take you more seriously when they see you’ve invested in recognized standards. But don’t mistake a cert for competence; it’s just a foot in the door. Results speak louder.

Growth and Specialization

Here’s how careers typically evolve:

- Entry Level: Supporting automation systems, assisting in code, wiring panels, or testing scripts

- Mid-Level: Leading smaller projects, designing control systems, writing full software test suites, coordinating across teams

- Senior-Level: Architecting complex systems, managing projects, mentoring junior staff, integrating advanced tech like AI or ML

- Leadership/Strategic Roles: Automation Lead, Engineering Manager, Director of Automation, CTO (in some startups or automation-centric companies)

Some specialize and go deep, becoming experts in a single platform or industry. Others go broad, learning enough across domains to lead large integrations or cross-functional teams.

The flexibility of this career is one of its biggest advantages. You can shift between industries, go from hardware to software, or climb the leadership track without hitting a ceiling.

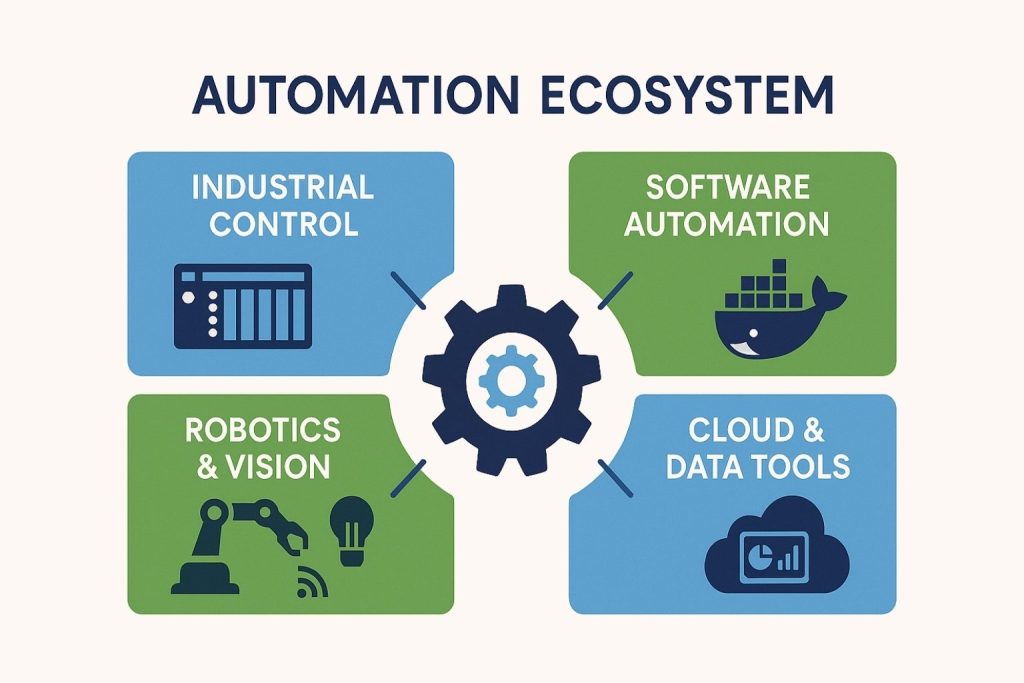

Tools and Technologies

The tools you use depend entirely on the industry you work in. But over the years, some core platforms and technologies have come up again and again.

Control and Industrial Automation

If you’re in manufacturing, food processing, energy, or pharma, you’ll live in this space:

- PLCs: Allen-Bradley (Rockwell), Siemens S7, Omron, Schneider

- SCADA Systems: Wonderware, Ignition, GE iFIX

- HMI Software: FactoryTalk View, WinCC, C-more

- Motion Control: Servo controllers, VFDs, stepper drives

- Sensors/Actuators: Optical, capacitive, inductive sensors; pneumatic cylinders; robotic arms

These tools form the physical backbone of industrial automation. You’ll program them, integrate them, debug them, and occasionally want to throw them out the window when things get weird.

Programming Languages and Frameworks

Your code is what glues the system together. Different environments demand different languages:

- Python: Scripting, test automation, data logging, ML integration

- Structured Text / Ladder Logic: PLC programming

- C/C++: Embedded systems and low-level device control

- Java, C#: Enterprise applications and QA test frameworks

- Shell scripting / PowerShell: IT and DevOps automation

- SQL: Data pipelines, process analytics

If you’re in DevOps or software test automation, you’ll also touch:

- Jenkins, GitLab CI/CD

- Selenium, Cypress, Postman

- Docker, Kubernetes (for deployment automation)

Learning to use version control (Git) and tools like Jira, Confluence, or Trello is also essential. Documentation and collaboration matter.

Robotics and Smart Manufacturing

In more advanced plants or warehousing systems, you may also work with:

- Collaborative robots (cobots): UR, FANUC, ABB

- Machine vision platforms: Cognex, Keyence, OpenCV

- Simulation software: Siemens Tecnomatix, RoboDK

- IoT platforms: MQTT, Node-RED, OPC UA

The trend is toward integration, having a robot, a PLC, a vision system, and a cloud dashboard all talking to each other in real time.

Cloud and Data Tools

More and more, I find myself interfacing with:

- AWS/GCP/Azure for cloud automation

- InfluxDB, Grafana for time-series data

- Power BI, Tableau for reporting and visualization

- Python/R for analytics and process modeling

In organizations where data drives decisions, automation engineers become part of the analytics pipeline, feeding structured process data into tools that power business intelligence or predictive maintenance.

Salary Trends

Let’s talk numbers. Salaries in automation vary by region, experience, and industry, but across the board, this is a well-compensated field.

United States

- Entry-level: $70,000 – $85,000

- Mid-level (3–5 years): $95,000 – $120,000

- Senior-level: $130,000 – $160,000+

- Specialized domains (e.g., pharma, AI, aerospace): Can exceed $180,000

The highest-paying sectors include biotech, energy, and enterprise software. Geographic hot spots include the Bay Area, Boston, Austin, and major manufacturing regions like Detroit.

Factors That Drive Pay

From experience, these are the biggest levers:

- Industry (regulated or high-risk sectors pay more)

- Hands-on skills (can you do the thing, not just talk about it?)

- Communication (if you can explain your system to executives, your value goes up)

- Leadership (project management, team coordination)

- Specialization (machine vision, AI, cybersecurity, etc.)

Automation is seen as ROI-driven. If you can demonstrate that you’ve saved time, improved yield, reduced downtime, or enhanced quality, you will always have leverage in salary conversations.

Career Outlook and Future Growth

I’ve never seen the field of automation move faster than it is right now. The forces driving demand are no longer just productivity and cost savings. We’re talking about global labor shortages, supply chain resilience, sustainability mandates, and digital transformation, all pushing companies to automate, rethink, and scale.

Demand Is Outpacing Supply

Automation engineers are in high demand, and we’re not just talking about industrial plants anymore. I’ve worked with clients in healthcare, fintech, logistics, biotech, energy, and even government sectors, all looking to automate something. It could be lab testing, regulatory reporting, customer support, data movement, or entire production lines.

A few reasons why demand is surging:

- Industry 4.0 is no longer a buzzword. It’s being implemented.

- Labor shortages are forcing companies to automate or stall.

- Global competition is squeezing margins companies are automating to stay alive.

- AI and cloud integration are making automation more powerful and accessible than ever.

Even in sectors like finance and insurance, RPA (robotic process automation) has opened doors for automation engineers to manage “digital workforces” that replace mundane human data tasks.

Emerging Specializations

You don’t need to pigeonhole yourself into one type of automation. In fact, many of us find new opportunities by leaning into emerging subfields.

- AI-Powered Automation: Integrating machine learning for predictive systems, computer vision, and anomaly detection

- Edge and IoT Automation: Building systems that collect, process, and act on data locally, especially in energy or agriculture

- Automated Robotics: Programming mobile robots, drones, and AGVs for logistics, inspection, and safety monitoring

- Cybersecurity for Automation: Securing connected industrial systems from threats, growing demand in utilities and pharma

- Cloud Automation: Infrastructure as code, cloud-native applications, and automated scaling for SaaS platforms

The point is, automation is becoming more contextual, more data-driven, and more strategic. If you can combine domain expertise with automation skills, you’re indispensable.

Global Trends Shaping the Profession

Here’s what I see shaping the next decade of automation engineering:

- Sustainability mandates will drive green automation: energy monitoring, waste reduction, and optimized resource use.

- Remote operations will become standard: from SCADA dashboards in the cloud to robots managed across time zones.

- AI copilots will assist engineers: design, simulation, and even control tuning will be supported by intelligent agents.

- Interdisciplinary fluency will be expected: the best automation engineers will understand business, operations, and analytics, not just code and wires.

And let’s be real, automation isn’t just a tech trend. It’s a survival strategy for businesses that want to stay lean, flexible, and competitive in the next economic cycle.

Industry-Specific Applications

Let’s bring this down to the ground. Here’s how automation engineering plays out across industries. These are not theoretical use cases. These are things my colleagues and I have built, fixed, optimized, or expanded.

Manufacturing and Industrial Control

This is the original stomping ground for automation engineers. Here, we’re replacing human labor in repetitive, dangerous, or high-precision tasks. Think:

- Robotic welders in automotive

- Vision-guided pick-and-place systems in electronics

- Automated mixing and filling lines in the food and beverage industry

- Conveyor systems and palletizers in distribution

Your toolkit in this space is usually PLCs, SCADA, VFDs, HMIs, and a lot of I/O modules. Uptime is king. If the line stops, the company bleeds money. You need fast diagnostics, bulletproof design, and supportability.

There’s also a growing trend toward self-healing line systems that can detect and respond to faults automatically without stopping production. That’s where advanced control logic, predictive analytics, and smart sensors come into play.

Software Development and QA

In the digital world, automation engineers make sure code gets tested, shipped, and monitored without manual friction.

Here’s what that looks like:

- Creating automated test suites for web/mobile applications

- Integrating with CI/CD pipelines to run regression tests on every commit

- Building performance and load testing frameworks

- Automating environment provisioning with tools like Docker and Kubernetes

If you’ve worked in DevOps, you already know the value of automation testing, deployment, monitoring, and rollback, all benefit from scripting and orchestration. The difference between a good and great software release often comes down to how well it’s automated.

In these roles, you need strong scripting skills, a deep understanding of QA methodologies, and experience with tools like Selenium, Jenkins, GitLab, Cypress, Postman, and cloud services.

Robotics and Advanced Manufacturing

This is where automation gets exciting and complicated. We’re talking about:

- Collaborative robots (cobots) working alongside humans

- Autonomous mobile robots (AMRs) in logistics

- Automated guided vehicles (AGVs) moving materials across factories

- Machine vision systems are doing real-time inspection and classification

In robotics-heavy environments, we blend motion control, machine vision, and software logic. Here’s where tools like RoboDK, ROS, Cognex, and URSim come into play. You’re often working with 3D simulation environments, sensor fusion, and real-time decision-making systems.

One of the more rewarding projects I worked on involved automating defect inspection using vision systems, tied into a sorting mechanism driven by a delta robot. We took human error out of the loop entirely and cut false negatives by 80%.

This is also the domain where AI is making the biggest dent. Robots that adapt their behavior based on feedback, adjust grip strength on the fly, or optimize their motion paths using reinforcement learning aren’t science fiction anymore; they’re deployed.

Healthcare and Biotech

Healthcare doesn’t usually scream automation. But it’s growing fast here, especially in laboratories, pharma, and device manufacturing.

Examples:

- Automated blood sample handling in diagnostic labs

- Pill counting and packaging in pharmacies

- Robotic-assisted surgery systems

- Data movement across EMRs and billing systems

- Automated environmental monitoring in sterile production

The challenge here isn’t just complexity, it’s regulation. You need validation protocols (IQ/OQ/PQ), compliance with standards (FDA, ISO 13485), and audit-ready documentation. But if you’re detail-oriented and can navigate regulated environments, this field is lucrative and impactful.

Energy and Infrastructure

Automation is the silent engine of critical infrastructure:

- Remote-controlled substations

- Pipeline flow control systems

- Smart grid management

- Wind turbine automation

- Solar farm telemetry and optimization

The focus here is resilience, safety, and uptime. Engineers in this space work with telemetry systems, wireless networks, SCADA, RTUs, and increasingly, cloud-based dashboards. Cybersecurity is also a huge concern; if a power grid is compromised, it’s not just a business problem, it’s a national one.

Logistics, E-commerce, and RPA

Think Amazon warehouses, automated storage and retrieval systems (ASRS), or bots handling returns. These environments are all about throughput, speed, and zero-touch fulfillment.

Here’s where automation engineers:

- Integrate barcode scanners, sorters, AGVs, and conveyors

- Create tracking and routing algorithms

- Manage automated packaging lines

- Use RPA to streamline back-office tasks (order reconciliation, vendor onboarding, invoice processing)

I’ve also worked on projects where bots handled repetitive finance workflows, generating reports, transferring data, and even sending alerts. That’s automation too, and it’s growing rapidly in enterprise environments.

Final Thoughts

Automation engineering is no longer confined to factory floors or backend scripts. It’s a strategic role that bridges physical systems and digital intelligence. It demands fluency in technology, awareness of business impact, and the mindset of continuous learning.

If you’re a company leader: invest in automation not as a one-off fix, but as a foundational capability. If you’re an engineer, keep building range and depth; your versatility is your advantage.

Automation isn’t replacing us. It’s amplifying what we can do. And in the hands of the right people, it’s nothing short of transformative.

About RiseOpp & How We Can Elevate Your Automation Strategy

As automation continues shaping how businesses scale their operations and optimize decision-making, its impact on organic visibility has become increasingly significant. Modern SEO practices now rely heavily on automated systems to streamline analysis, enhance content performance, and support long-term growth, especially when viewed through the lens of SEO automation and its growing role in competitive digital strategies.

As the pace of innovation accelerates across industries, companies that want to stay competitive can’t just build automation systems; they also need to tell their story, amplify their impact, and connect that automation work to business growth. That’s where we at RiseOpp step in.

We’re a leading Fractional CMO and SEO services firm with deep experience helping B2B and B2C organizations of all sizes drive growth in the age of AI. When you engage with RiseOpp, you gain our proprietary Heavy SEO methodology, designed to rank your website for tens of thousands of keywords over time so the value you create through automation gets seen, found, and understood by your customers and partners.

You also gain Fractional CMO-level guidance on branding, messaging, marketing strategy development, and building the right marketing team to support your automation-driven transformation. Our team delivers a full stack of execution across channels including SEO, GEO, PR, Google Ads, Meta Ads, LinkedIn Ads, TikTok Ads, email marketing, and affiliate marketing, all aligned with your automation objectives and business KPIs.

If your organization is deploying automation systems, whether in manufacturing, logistics, digital operations, or enterprise software, you don’t just want to operate efficiently. You want to communicate intelligently, capture the value you’ve unlocked, and scale it across markets. RiseOpp acts as your strategic marketing partner in that journey.

Ready to move from automation capability to market leadership? Reach out to our team today, and let’s map how your automation roadmap and your growth trajectory can align full throttle.

Comments are closed